Trends and Challenges in the Electricity Industry

- Electricity consumption will double by 2050

- By 2035, almost half of the total global electricity capacity will be solar and wind

- Equipment modernization, digitalization and AI

- Regulations that increase competition and allow for flexibility in business models

Comping solution - Prevention of non-technical losses

Meter modernization is a risky moment where the meter is installed and embezzlement of the meter is possible

High non-technical losses, in addition to direct financial loss, make it difficult to plan spending, which can also indirectly cause financial loss

Why Comping NTL Solution?

Technology leader according to all relevant analysts (Gartner, Forrester, Chartis, IDC) in several key areas.

An analytics platform that enables data to be transformed into actionable insights at scale, detecting hidden losses and predicting risks.

Comping NTL solution in one of Europe's largest DSOs.

Comping NTL is operational in one of the largest electricity distributors in the EU, with over 3 million meters.

This is concrete proof of the functionality, scalability and resilience of the system in a real environment.

Deep integration with the SAP IS-U system.

Comping NTL was developed with full support for SAP IS-U, an ERP system used by over 200 ODS in Europe.

This means lower integration costs, a shorter implementation timeframe, and better alignment with internal business processes.

Quantified benefits for ODS

Detection

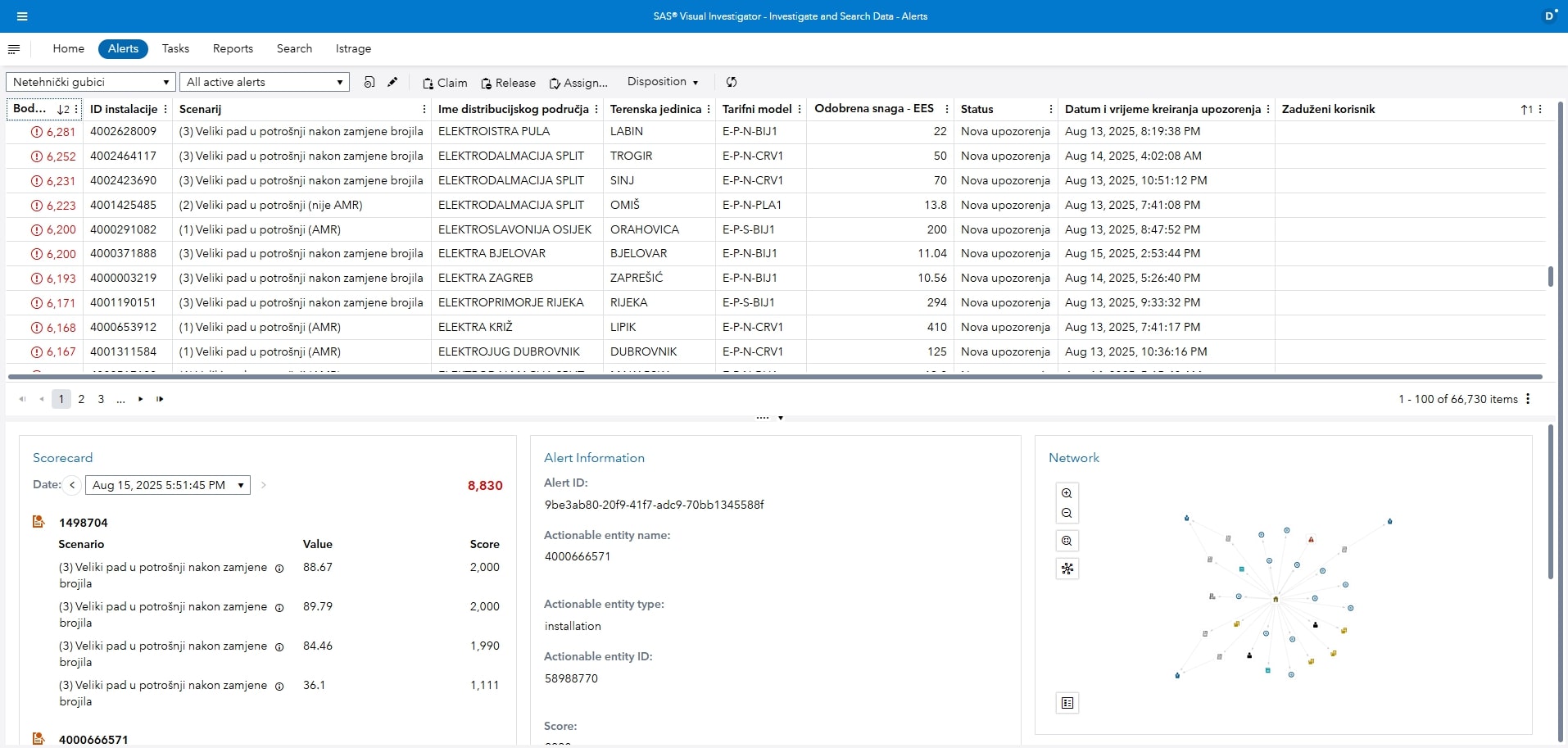

more detected cases, as a result of advanced analytical scenarios, which combine about 20 variables/parameters, 3-5 filter algorithms and 3-5 scoring algorithms to create alerts that then go into triage

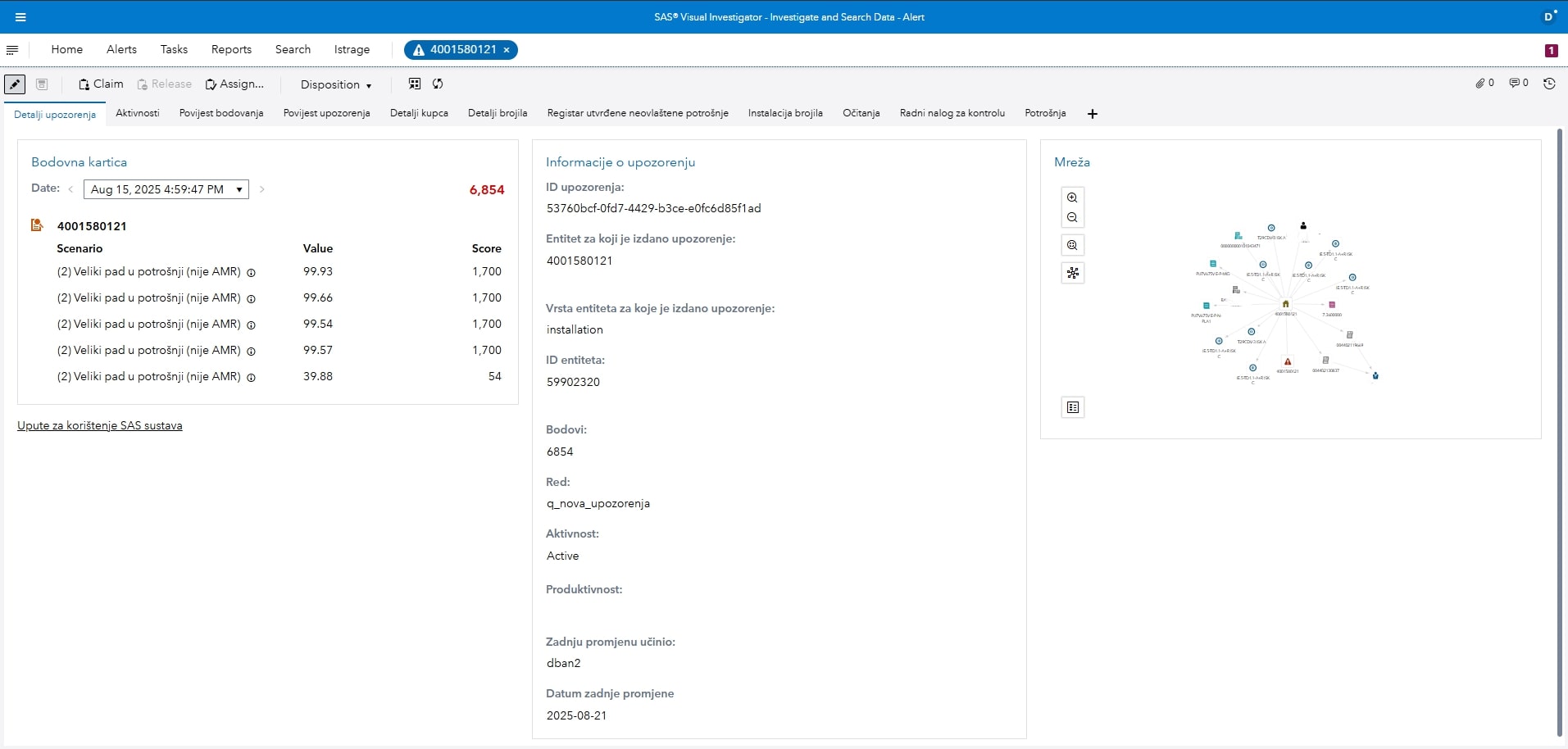

Triage

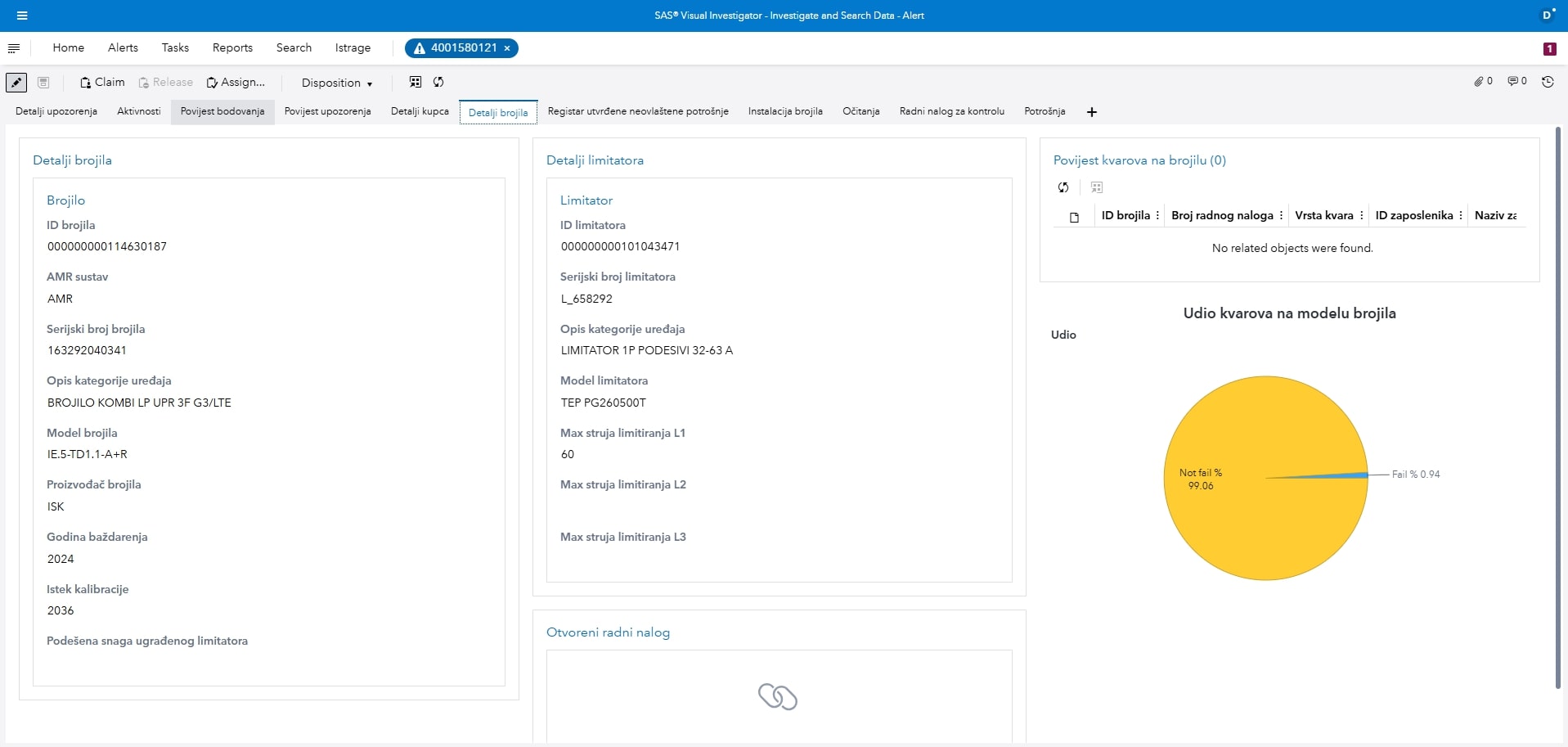

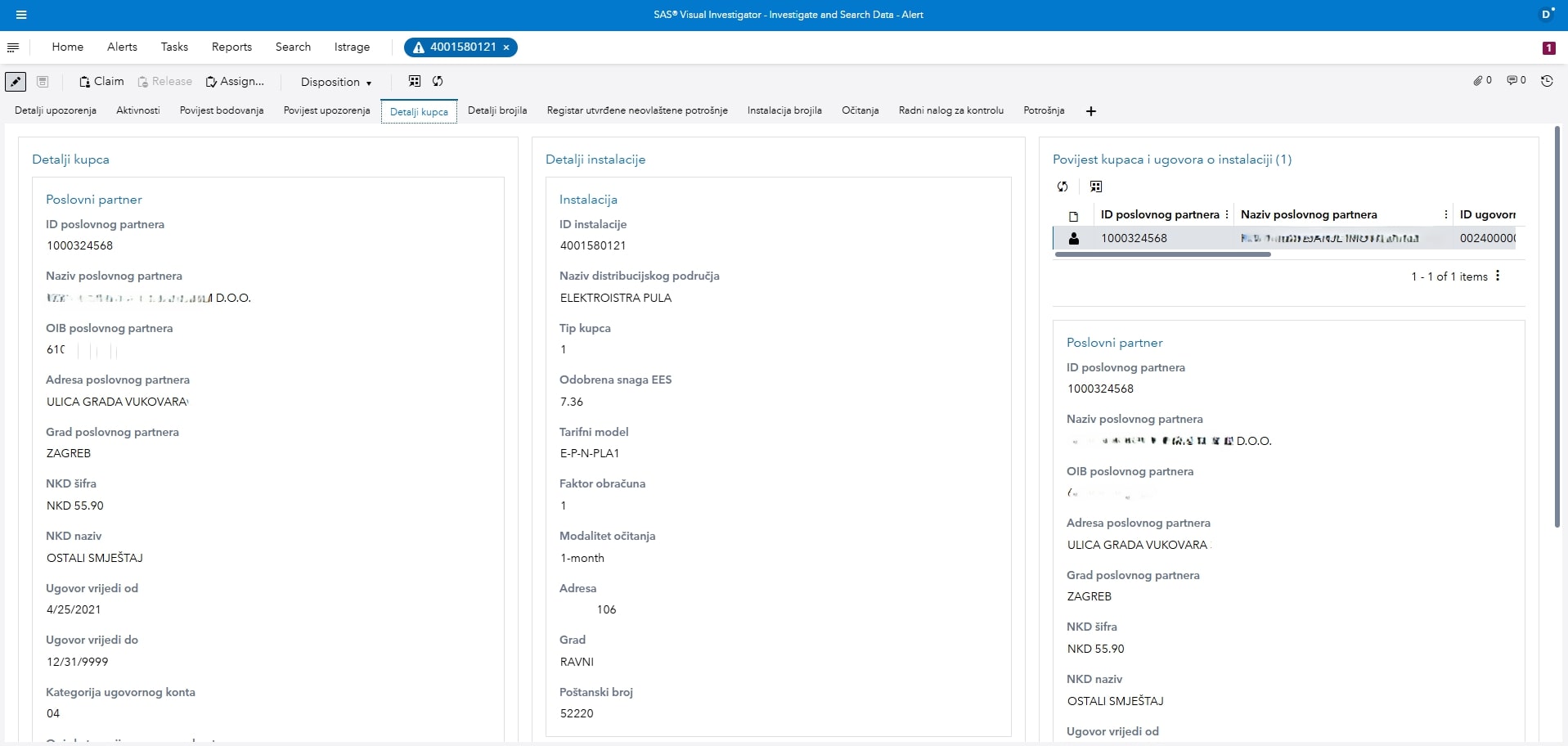

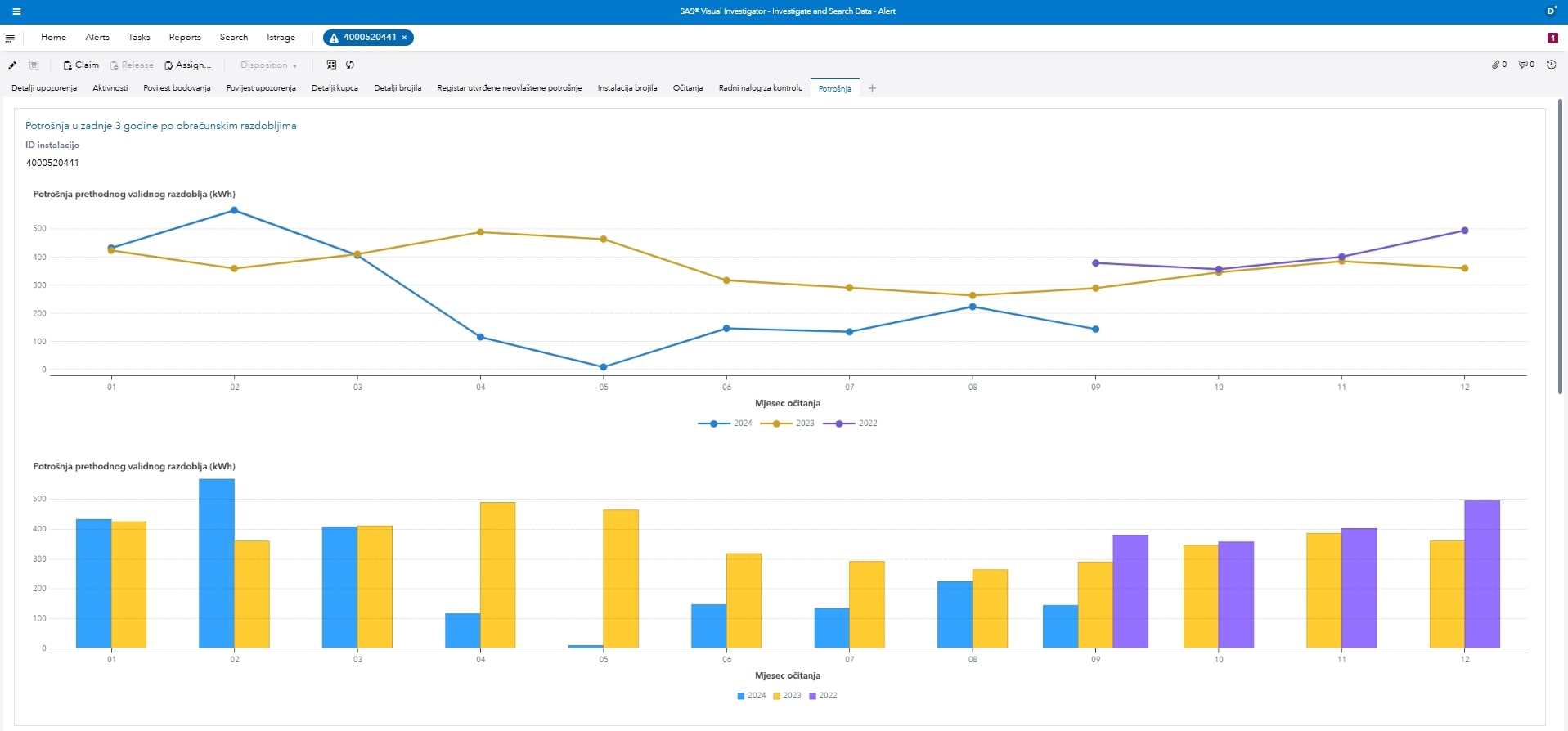

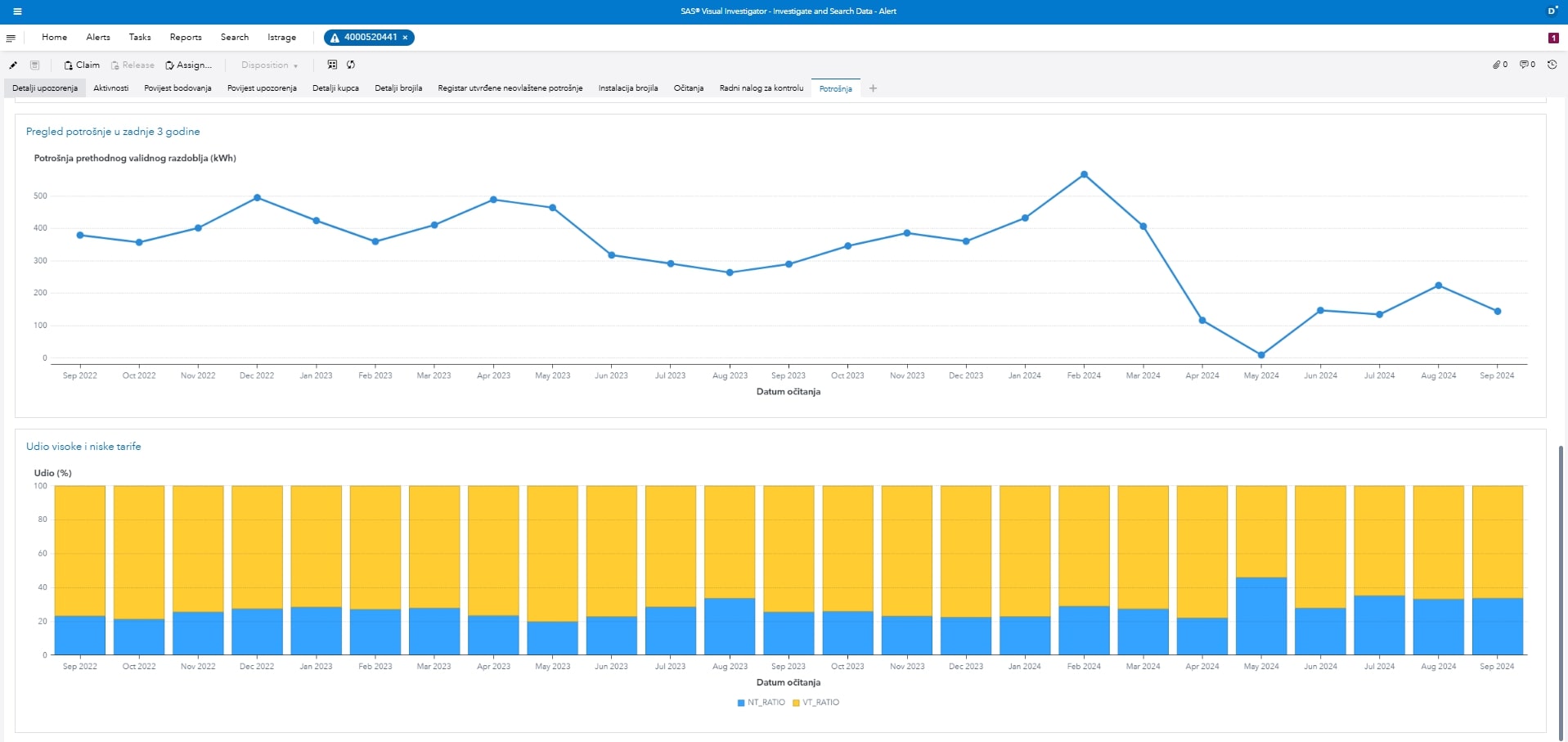

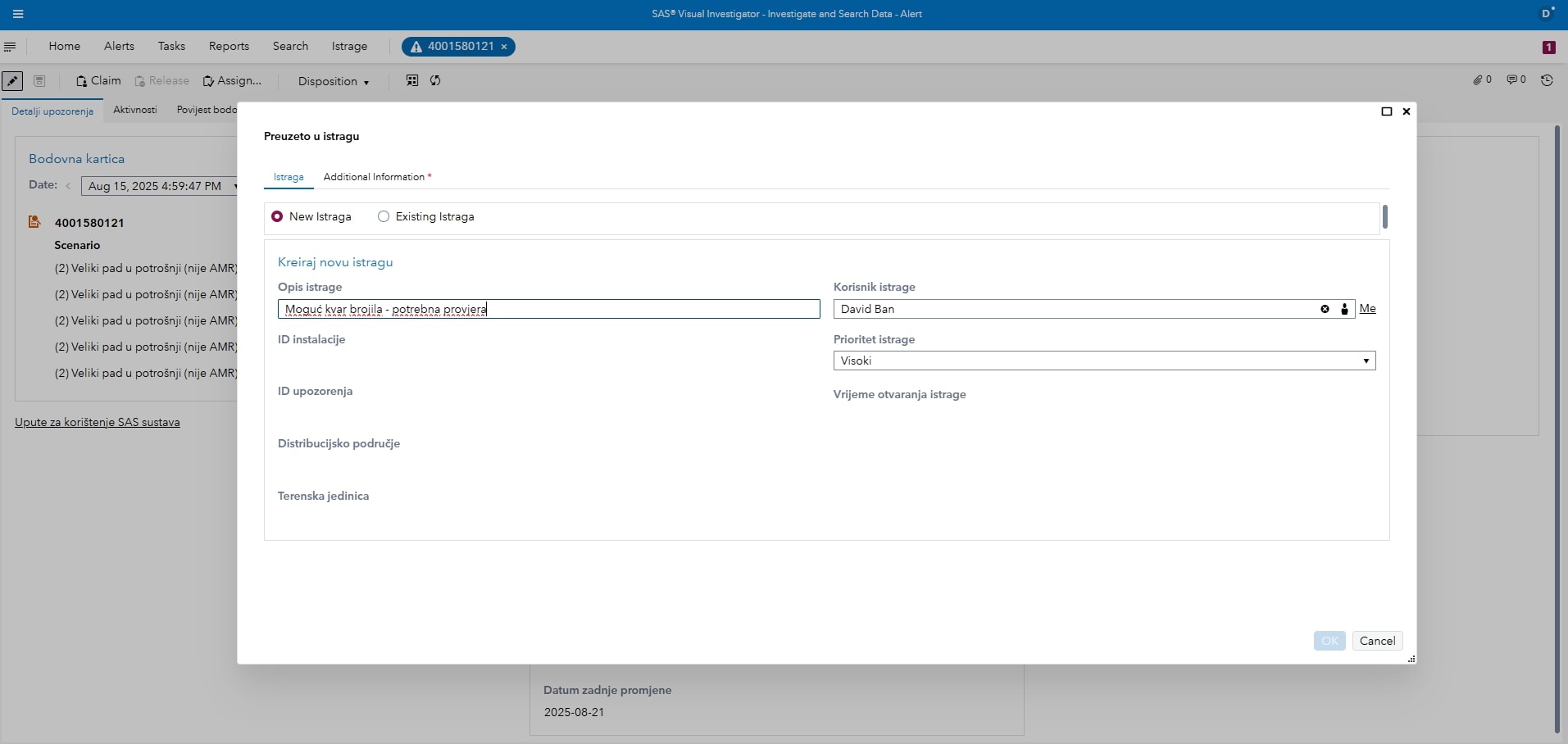

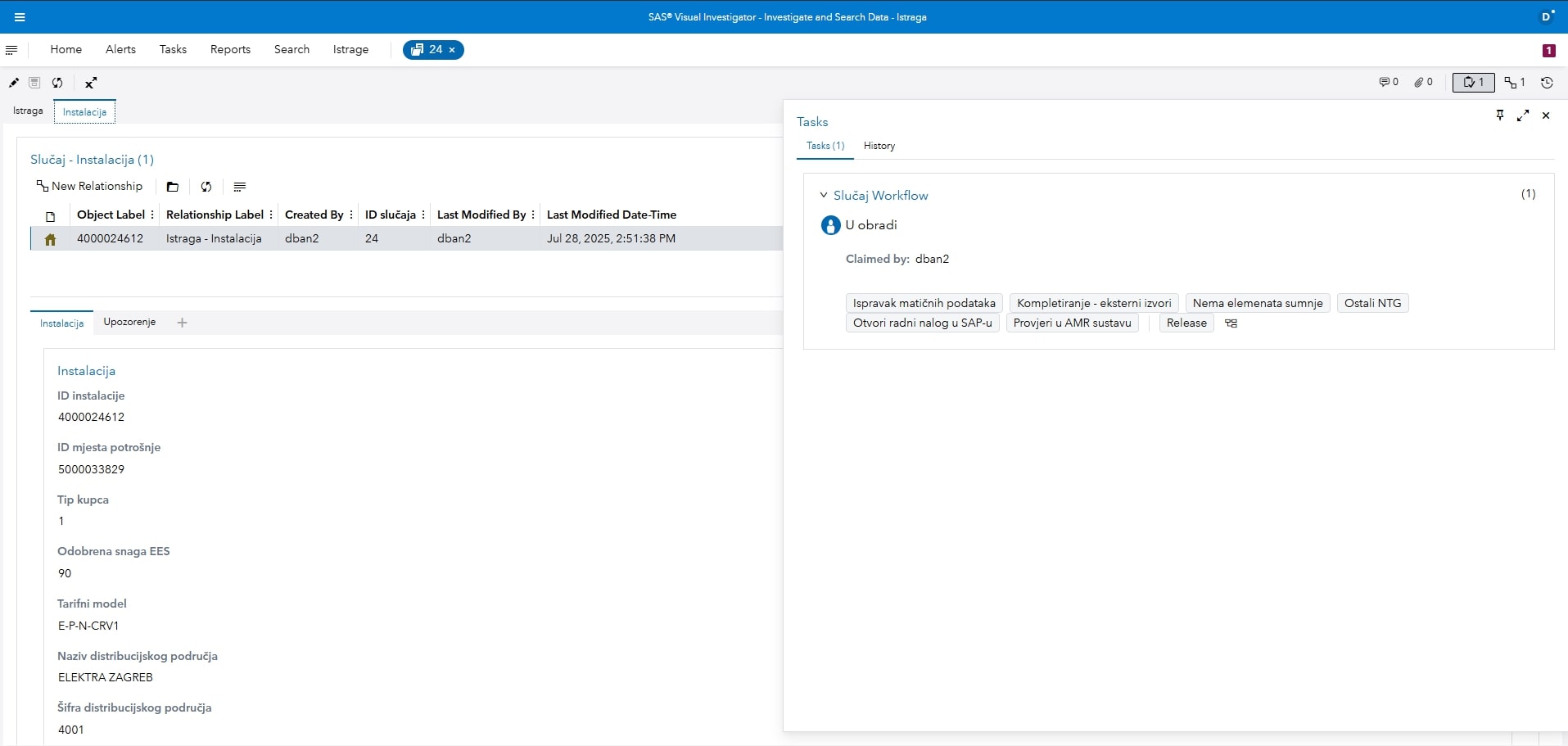

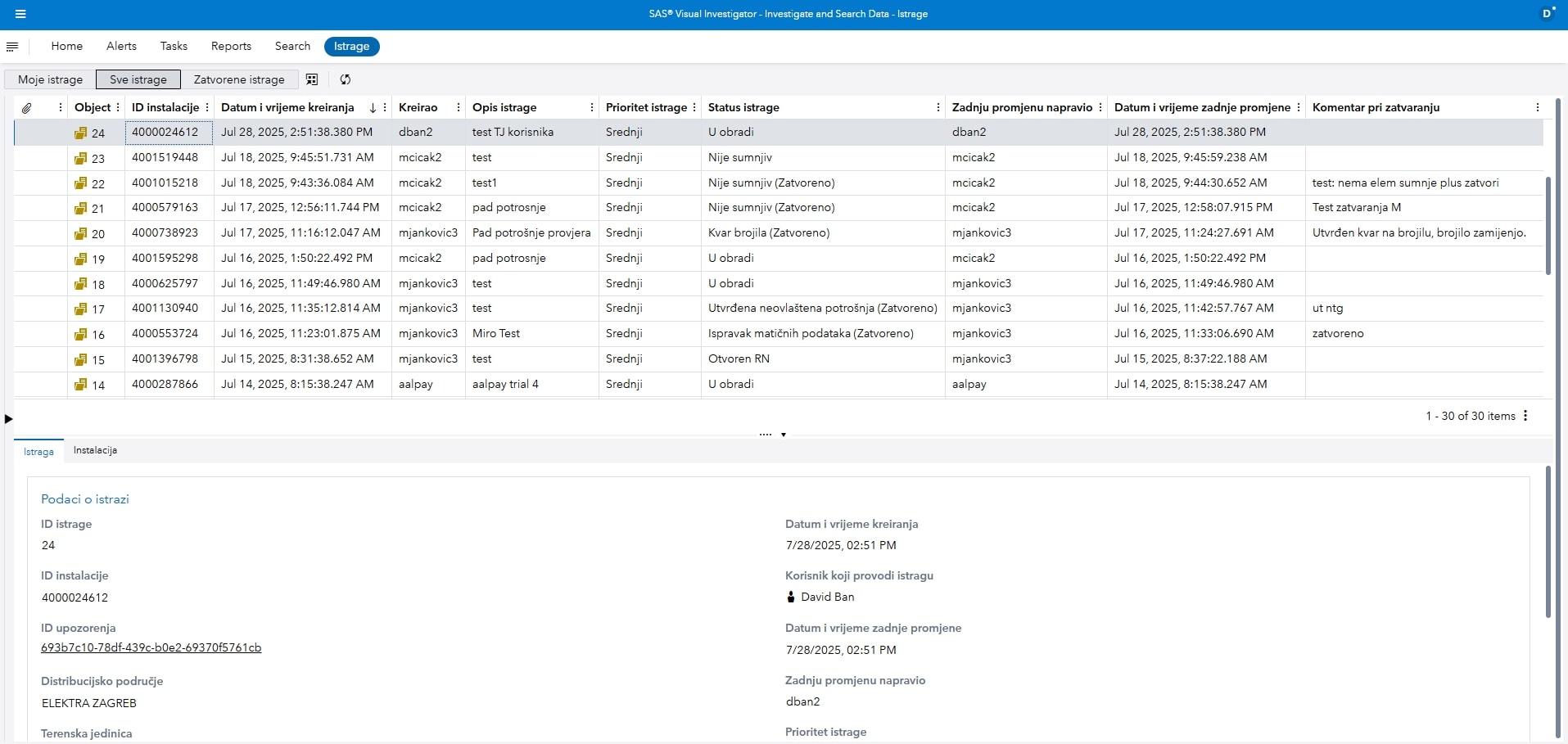

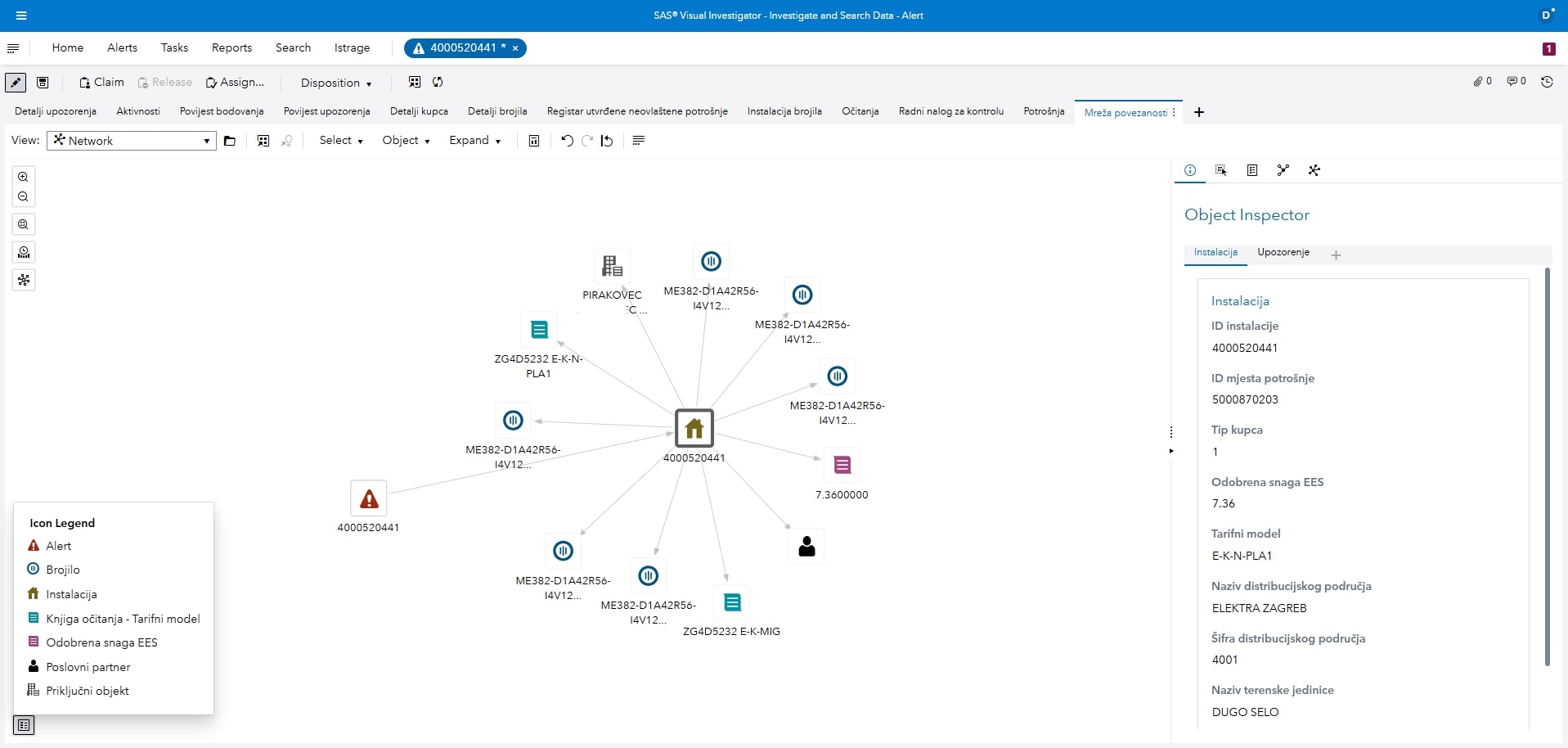

An investigator can triage 20 times more cases through the NTL system (600-800 per month per investigator), and this is enabled by specially developed 12 user interfaces through which he has available information about installation, customer, meter, readings, consumption, work orders, meter replacements, consumption, production...

Investigation

better success rate of investigations, which was previously at levels of about 2% and with the use of NTL systems is about 50%, and is the result of advanced analytical detection (rather random sampling of field controls) and advanced user interfaces in the triage phase that enable the rejection of false-positive cases

Savings

greater savings resulting from advanced analytical detection, triage and investigation through which resources in the field (field controllers) are directed to really suspicious cases where the success rate of the investigation is then very high (about 50%), which affects the growth of direct savings

Words from our satisfied customers

During 2024, a total of 74,715 physical inspections of connections and metering points were carried out in the field. Taking into account the average cost of one control (including labour, transport, equipment and other operating costs) of EUR 22.55 per control, the total cost of the field activities was around EUR 1.68 million. Out of the total number of inspections, 11,321 technical failures in measuring equipment (e.g. meters, tariff switchers, wrong connections, etc.) and 589 cases of unauthorized electricity consumption were identified. This means that only in 15% of all controls carried out non-technical loss was detected, which indicates the limited effectiveness of classical detection methods.

However, a significant step forward was made during the trial period of the application of the new system based on SAS technology, between March 25 and April 11, 2025 (a total of 14 working days). During this period, 376 office investigations were automatically opened based on data and samples from the system. Of these, 177 cases ruled out suspicion of irregularities, while 58 investigations are still ongoing. In the remaining 141 cases, based on the field controls, 60 actual irregularities were confirmed, which are classified as non-technical losses – which represents a detection efficiency of 43%. If we compare this with the results from 2024, it is clear that the new approach increases detection efficiency many times over – from 15% to 43%. Using the SAS system, only 26,328 field inspections would be required to detect the same number of irregularities.

This would represent a cost of €594,000, which means that the new system allows us to achieve the same result with cost savings of approximately €1.086 million.

Source: Razvijanje metoda za analizu podataka kako bi se omogućila brza reakcija na promjene u potrošnji i kvarove, HRVATSKI OGRANAK MEĐUNARODNE ELEKTRODISTRIBUCIJSKE KONFERENCIJE - HO CIRED, 9. (15.) savjetovanje, Šibenik, 25. - 27. svibnja 2025.